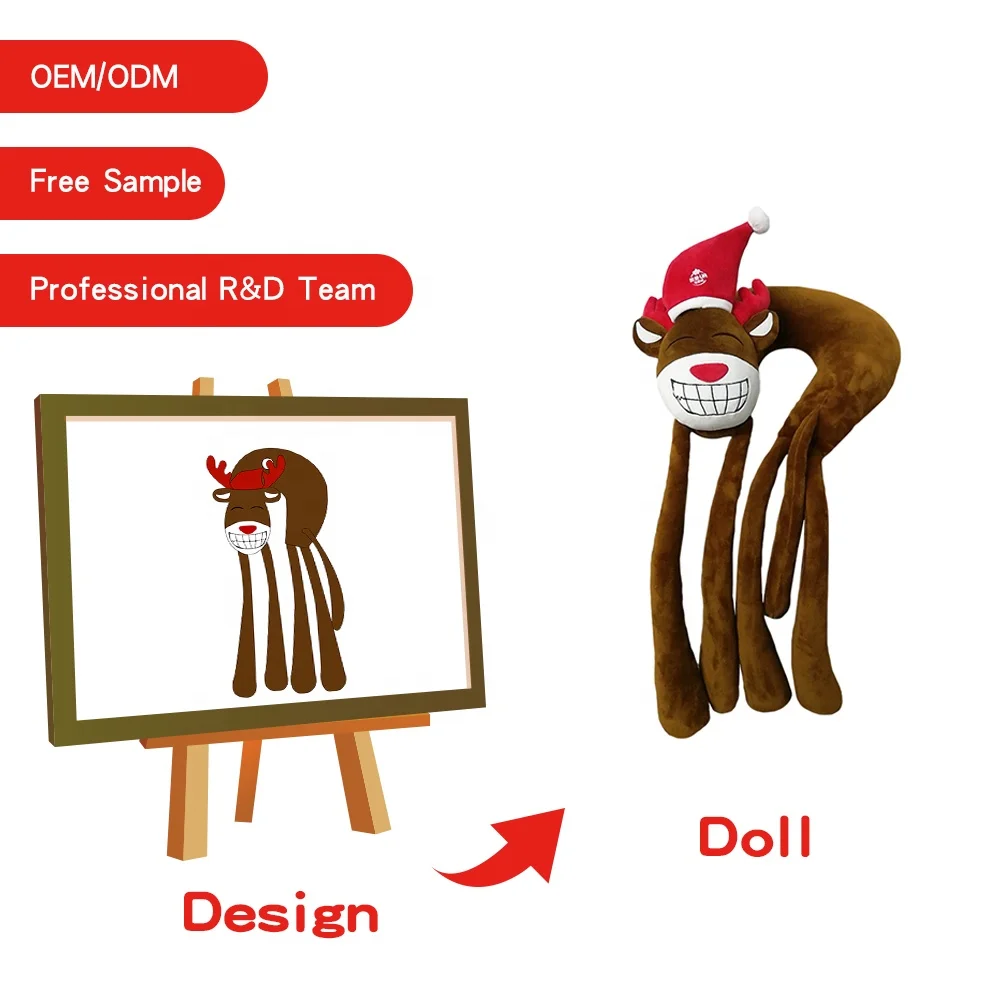

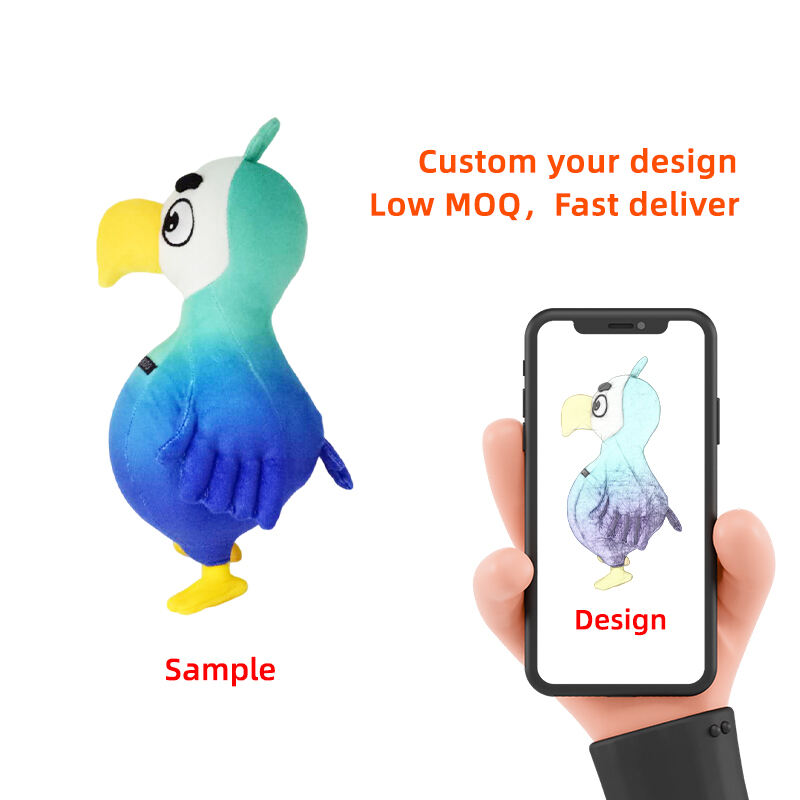

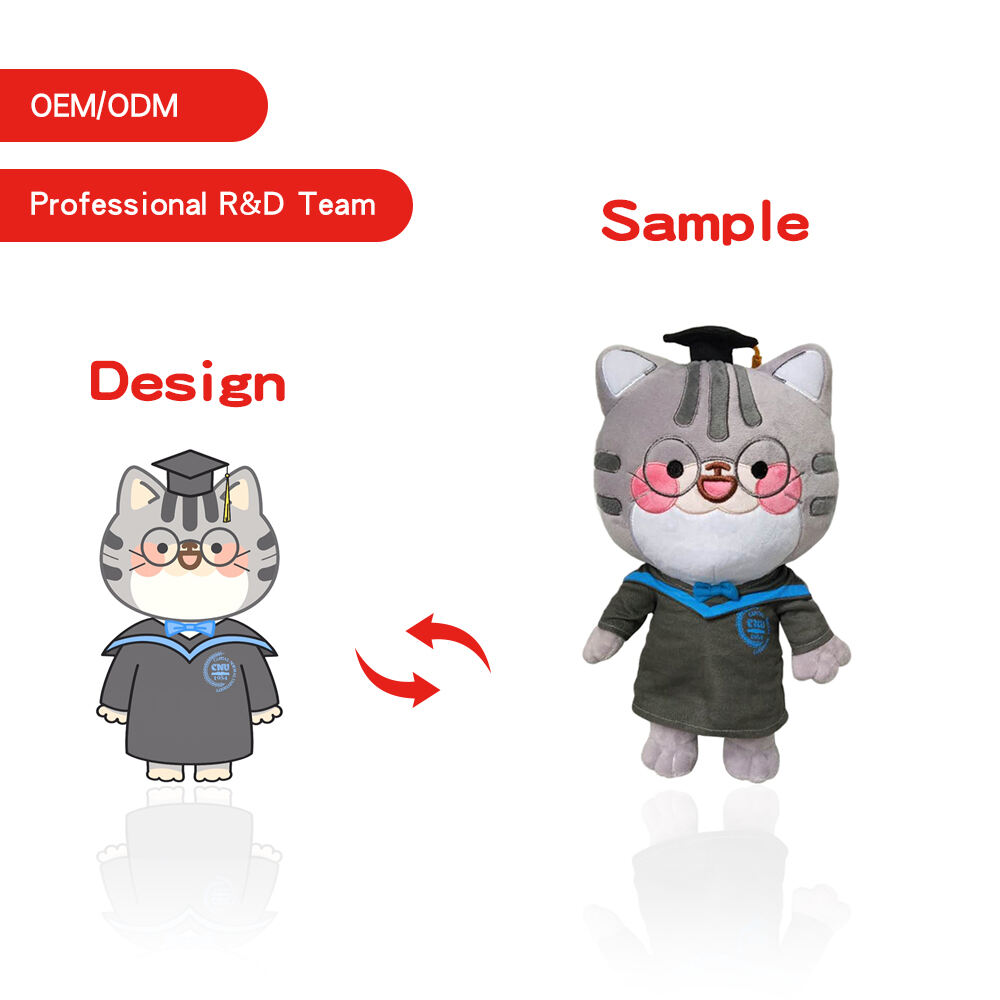

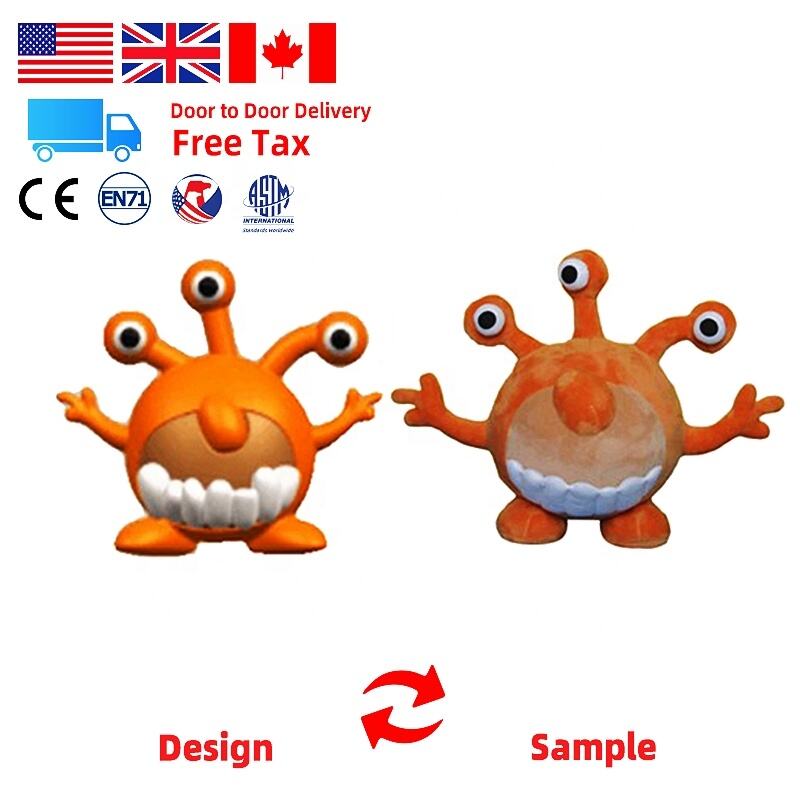

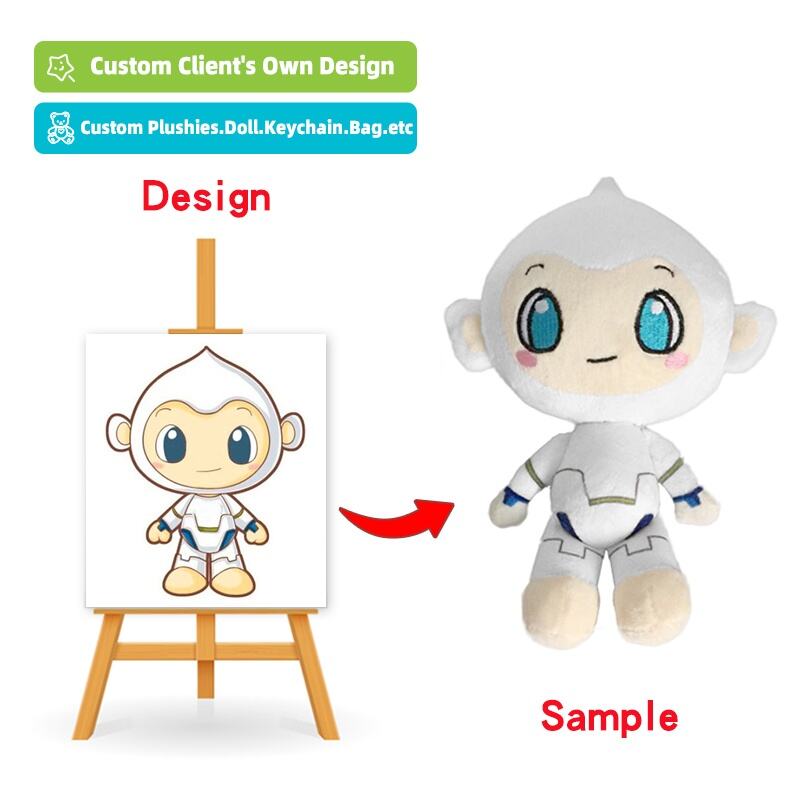

Unlimited Customization Options and Creative Flexibility

Custom plush makers excel in providing unlimited customization options and creative flexibility that transform abstract concepts into tangible, emotionally engaging products tailored to specific brand identities, personal preferences, and market requirements. The customization spectrum encompasses every aspect of plush toy design, from basic structural modifications to complex character development projects that require specialized materials, unique construction techniques, and innovative assembly methods. Size customization options range from miniature collectibles measuring just a few inches to oversized display pieces exceeding several feet in height, accommodating diverse application needs including desktop accessories, retail merchandise, promotional giveaways, and architectural installations. Material selection possibilities include premium organic fabrics, hypoallergenic synthetic alternatives, specialty textures like faux fur and velvet, moisture-resistant treatments for outdoor applications, and eco-friendly options that support sustainable manufacturing initiatives. Color customization extends beyond standard fabric selections to include custom dyeing services, gradient color transitions, multi-tonal effects, and specialty finishes that create unique visual characteristics impossible to achieve through conventional manufacturing methods. Feature customization enables clients to specify intricate details such as embroidered facial expressions, removable clothing accessories, interactive elements like sound modules or LED components, magnetic attachments, and articulated limbs that enhance play value and collector appeal. Custom plush makers accommodate complex brand integration requirements, incorporating logos, mascot characteristics, corporate colors, and marketing messages seamlessly into product designs while maintaining aesthetic appeal and structural integrity. Packaging customization options include branded boxes, protective wrapping materials, informational inserts, and retail-ready presentation formats that enhance perceived value and support marketing objectives. The creative flexibility offered by custom plush makers extends to rapid prototyping services, design iteration capabilities, seasonal modification options, and limited edition production runs that enable clients to test market responses, celebrate special events, and create exclusive collector items that generate enhanced customer engagement and brand loyalty.